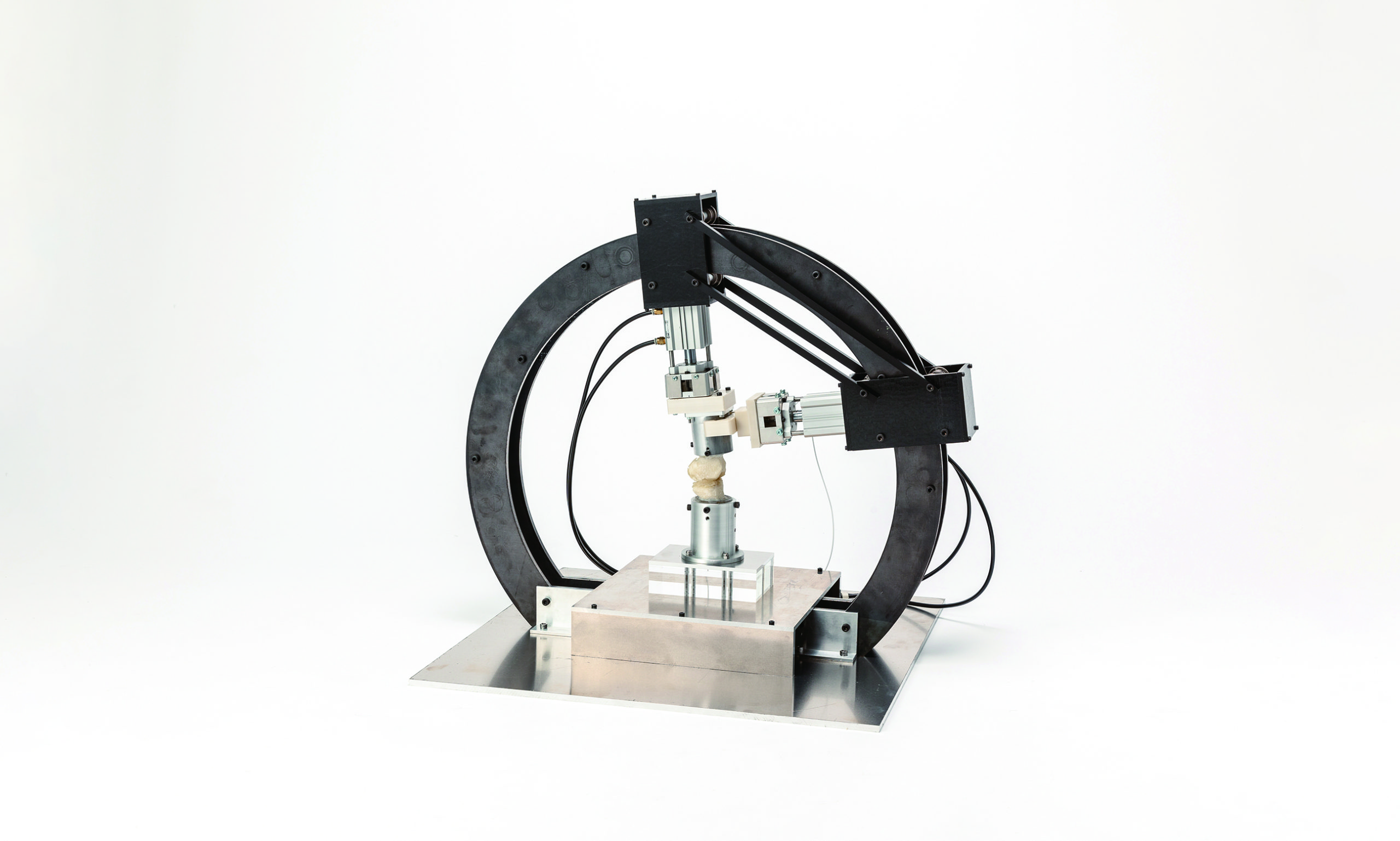

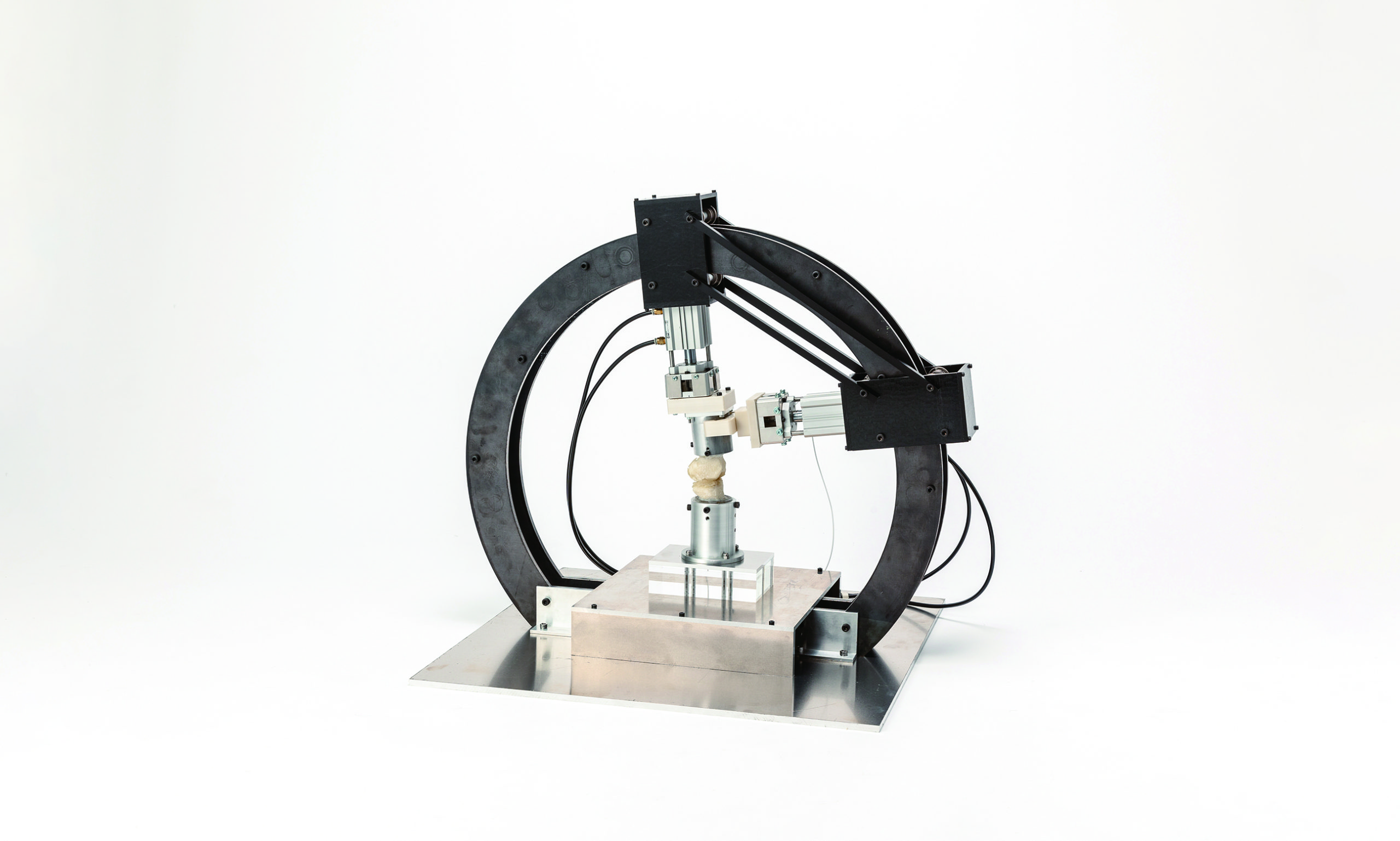

ヒトの膝関節実模型を用いた関節負荷計測装置Joint Stress Measuring Device Using Human Accurate Shape Knee Joint Model

精密工学専攻Department of Precision Engineering

本装置は、膝関節の実形状模型を用いて起立動作時の膝関節にかかる力の分布を静的・動的に計測するために製作されました。

骨の模型は、ヒトの大腿骨、脛骨、半月板のCT画像とMRI画像より得られた3Dデータをもとに3Dプリンタで製作されました。大腿骨の動作データは、モーションキャプチャーで計測したヒトの起立動作のデータをもとに作成されました。

また、大腿骨の長軸方向とそれと垂直方向にかかる力の時系列データは、筋骨格シミュレーター(SIMM)を用いて求められました。脛骨を固定し、大腿骨をロボットアームで動かしながらエアシリンダを用いて大腿骨に二方向から力を印加することで、起立動作における膝関節への負荷を再現します。エアシリンダで印加する力は、圧力センサーで検出されフィードバック制御されます。膝関節内に薄膜圧力センサーを設置することで、膝関節内にかかる圧力の分布やその時間変化を計測します。

ヒトの膝関節実模型を用いた関節負荷計測装置

2013

寸法:700×700×600

所蔵:東京大学 大学院工学系研究科 精密工学専攻 淺間・山下研究室

ロボットアームで大腿骨を動かしながらエアシリンダで大腿骨の長軸方向とその垂直方向に力を加えることで、起立動作中の膝関節にかかる負荷を再現。

This device was made to statically and dynamically measure the distribution of stress applied to the knee joint during standing up motion using an accurate shape model of human knee joint.

The bone model was made with a 3D Printer based on 3D data obtained from CT images and MRI images of human femur, tibia and meniscus. The femur motion data was created based on human standing up motion data measured by motion capture camera. In addition, the time series force data of the longitudinal direction of the femur and its perpendicular direction were obtained using a musculoskeletal simulator (SIMM).

By immobilizing the tibia and moving the femur with the robot arm and applying force to the femur from two directions using the air cylinder, the stress on the knee joint during standing up motion is reproduced. The force applied by the air cylinder is detected by the force sensor, and feedback controlled. The pressure distribution in the knee joint and its change over time are measured by installing thin film pressure sensor in the knee joint.

Joint Stress Measuring device Using Human Accurate Shape Knee Joint Model

2013

Size: 700×700×600

Collection: Asama and Yamashita Lab, Department of Precision Engineering, School of Engineering, The University of Tokyo

The stress applied to the knee joint during the standing up motion is reproduced by moving the femur with the robot arm and applying force with the air cylinder in the longitudinal direction of the femur and its perpendicular direction.